Concept and History of the Horizontal Separator Panel

Most of the selective devices and gears have been designed and developed from fishermens ideas. This gives rise to the idea that not all fishermen try to circumvent the system, but in any regulation or legislative rules there are law breakers. To enforce these rules and regulations we have to monitor the users, as in your own case Fisheries Enforcement.

Crimond has been at the forefront of many of the developments in species selective gears and devices in the Canadian fishery. In fact we are the first gear company to market Horizontal Panels commercially.

Knowledge of fish behaviour is essential to the design of selective fishing gear and devices.

This information is usually gathered by using underwater cameras in the vicinity of fishing gear used in a real time environment.

Fishermen, and gear technologists, can then design fishing gear to target the desired species and release unwanted bycatch, or species on restricted quotas.

These include selectivity grids which are now used in a variety of fisheries but mainly in the Shrimp and Silver Hake fisheries.

The device we will see today is the Horizontal Separator Panel as opposed to the Vertical Separator Panel. The first experiments with the Horizontal Separator Panels, as far as we know, were conducted in Scotland, where experiments with as much as three panels at different heights in the same trawl have been tried.

This Horizontal Separator Panel is designed to separate species and the use of this panel in Canadian Fisheries is based on the behaviour of two species, Cod and Haddock.

Using underwater cameras it has been observed that when haddock are entering a trawl they rise high and in many cases pass right over the headline of the trawl. Cod on the other hand have a tendency to keep low near the sea bottom. The horizontal separator panel takes advantage of this and the majority of Cod pass under the panel while Haddock rise over it.

The panel is designed so that the top codend retains all haddock, while the cod escape out of the lower codend which is left open.

The panel is normally attached to the fishing line by two or three strops which can be adjusted easily. The average strop length is set between two and three feet, but can differ according to the area and abundance of cod.

If the mesh size of the panel is large enough some migration of round fish from the lower area to the upper area may occur. However it is highly unlikely that species such as skate, monkfish, halibut, or any of the flatfish species are likely to do this. Any amounts of these species in the catch logs would indicate either of two scenarios.

Trawlers operating off Nova Scotia, Canada in areas such as Georges Bank have had excellent results using horizontal separator panels designed and manufactured by Crimond Enterprises to release cod while targeting haddock.

Fish behavior studies showed that haddock swim high when entering the trawl while cod have a tendency to keep low. Results from some vessels have shown, that even in areas with high concentrations of cod, the catch ratio of cod has been as low as 500 lbs of cod to 20,000 lbs of haddock. The horizontal panels have now been accepted commercially and are fitted and removed by fishermen when necessary. David Tait and DFO conducted some of the first commercial trials with horizontal separator panels in Quebec, Canada in the 1980s.

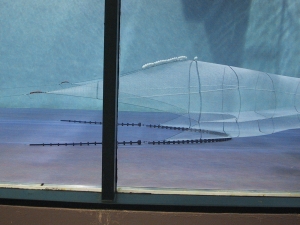

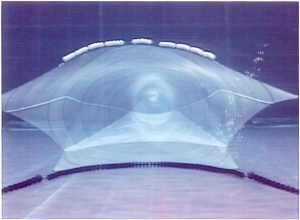

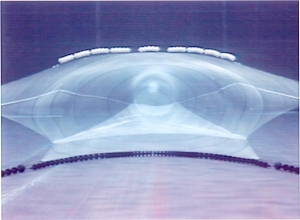

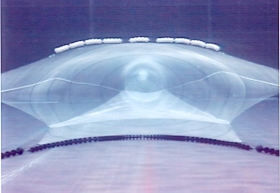

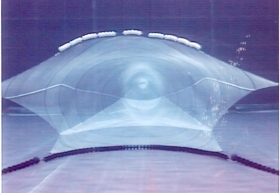

Below is further results of Flume Tank testing conducted by the company and National Sea Products.

One of the objectives was to observe how the panel performed with trawl distortions. The two camera shots show the trawl in #1 with 180 feet of door spread and then in #2 with 150 feet of door spread. In both scenarios the panel remained functional. The end result was another successful exercise by the trawling industry to establish a sustainable fishery.

Trawlers operating off Nova Scotia, Canada in areas such as Georges Bank have had excellent results using horizontal separator panels designed and manufactured by Crimond Enterprises to release cod while targeting haddock.

Fish behavior studies showed that haddock swim high when entering the trawl while cod have a tendency to keep low. Results from some vessels have shown, that even in areas with high concentrations of cod, the catch ratio of cod has been as low as 500 lbs of cod to 20,000 lbs of haddock. The horizontal panels have now been accepted commercially and are fitted and removed by fishermen when necessary. David Tait and DFO conducted some of the first commercial trials with horizontal separator panels in Quebec, Canada in the 1980s.

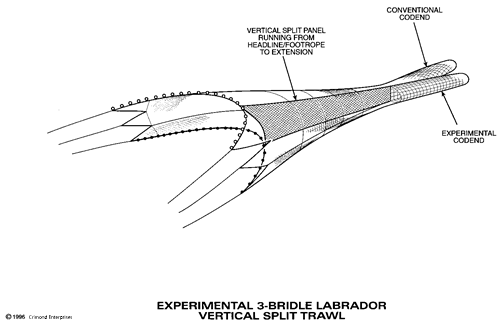

Concept and History of the Vertical Separator Panel

An evaluation project was designed as result of a separate Canadian Government/Industry initiative, to determine if a larger mesh size would be beneficial or otherwise to the Canadian offshore shrimp industry.

An experiment was conducted and was designed to reduce the ratio of industrial shrimp in the catch without incurring a loss of larger shrimp. Codends constructed of mesh larger than Canadian regulation size (40 mm) have been tried elsewhere, and there was much interest in the new 55 mm codend mesh regulation introduced in April 1993 in Greenland.

The objective of this experiment was to investigate, under commercial conditions, the selectivity characteristics and catch implications of codends constructed with mesh sizes of 45, 50, and 55 mm.

Unlike similar vertical split panels, which begin several meters behind the footrope, the panel design commenced at the Headrope and Footrope then ran back to the last belly where the separation of the extensions and codends took place. (see drawings) The main objective was to totally eliminate migration of shrimps from one side of the trawl to the other.

Results:

Little or no difference was found in the experimental codend mesh sizes during the survey.(see report)

The MV Northern Osprey@, a 66 meter vessel owned by M.V. Osprey Limited, was used for this experiment during April and May, 1993. Fishing was conducted in NAFO Subdivisions 2J and 3K, sub-areas 69, 6A, 6B, 6C, and 6E.